Call Us

-

-

Send Email

info@magnusindia.net

-

GST

27AAJPL0227B1Z8

Carburizing Heat Treatment

Carburizing Heat Treatment Services in Pune, Chennai, Bangalore/Bengaluru

Our Products

Our Services

“Genius Vacuum Technologies" is an extended arm of Magnus Industries established at Pune, Maharashtra, India, a Partnership firm, engaged as the foremost Manufacturer, Supply & service provider of Heat Treatment Furnace. Our products are high in demand due to their premium quality and timely delivery.

We have dynamic professional with over 28+ years of experience in the domain of Installation & Commissioning, Maintenance & Supply of…

- Ultra High-Vacuum systems (To produce Night Vision Tube).

- Vacuum Hardening & Brazing Furnaces.

- Physical & Chemical Vapor Deposition (PVD & CVD) Plants.

- All type Atmospheric & Seal Quench Furnaces.

- Plasma Nitriding & Gas Nitriding Furnaces.

- Highly Precision Fully automated multi axis "TurnMill & Profile Grinding" Machinery.

- Metal Injection Molding (MIM) like molding machine, De-binding & Sintering furnace.

- Additive manufacturing, 3D Printing machinery like Arcam EBM (Electron Beam Machine) & Stratasys FDM (Fuse Deposition Modeling) Plastic 3D printing machine.

- Utility Equipment’s like Air Compressor, DG set, LN2 plant, LPG plant, Ammonia plant, Centralize Cooling & Chilled water system, HT & LT Electrical installations & Fire Fighting System.

- Project planning & execution including Entire Infrastructure.

- All type Heat Treatment furnaces Hot Box refurbishing, repairing of allied equipment like Vacuum pump, Motor, Blowers etc.

- Designing, Developing & Indigenous the all type parts for Heat Treatment furnace.

- Supply of required allied equipment & Utility system like Close loop water system, Buffer Tank, Gases & Water Piping etc. for Heat Treatment furnaces.

- Dismantling, Shifting/relocate & re-installation of all type of Heat Treatment furnaces.

- Provided very special “Helium Leak Detection” service to all type of vacuum furnaces.

Genius is also engaged in operation and annual maintenance contract of heat treatment plant. We are supported by a team of highly skilled and experienced professionals, who possess years of experience in this domain. Our professionals provide these services in an excellent manner using the best quality tools and latest techniques. The offered services are widely appreciated by our clients for their flawlessness, promptness, high reliability and perfect execution. We perform these services as per the various requirements of our clients. To perform these services, our professionals interact with clients and provide them the best solutions as per their specifications.

Annual Maintenance Contract Of Heat Treatment Facilities

Genius Vacuum is working in the segment of Operation & Maintenance of Heat Treatment facilities of the furnaces like all types of Sealed quench , Low Pressure carburizing ( LPC ), GCF, Continuous Hardening furnaces, Mesh Belt, Washing machine, Shekhar Hearth, Bogie Type furnace, All type of Vacuum Hardening , Tempering, Annealing , Brazing f/c, Plasma Ion Nitriding ( Indian and Imported) and gas Nitriding furnaces.

We also extend our support for Installation and Commissioning of Heat Treatment plants right from the preparation of plant layout to selection and installation of utilities for the particular facility.

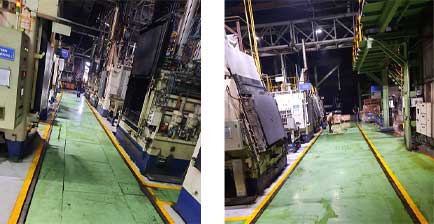

ACTUAL SITE PHOTOS OF LPC AND SQF, CLIENT – BHARAT FORGE LTD.

ACTUAL PHOTOS OF DOUBLE CHAMBER SQF PLANT – BHARAT FORGE LTD.

ACTUAL PHOTO OF 4 TON/ HR CONTINIOUS HARDENING PLANT, BARAMATI

We undertake below types of HT shop contracts

- Gross contract ( as per the deployment of staff , Joint study based )

- Net Contract ( At actual cost of operation and management fee )

- Labour supply and management fee

- Piece rate contract

- Annual maintenance contract ( Operation & maintenance of HT shop )

(Please Note - We follow minimum wage act as per factory act.)

We actively participate in the following drive of clients

- Safety Awareness program of client

- Work permit method

- Safety induction of new joinee

- Kaizen competition

- TPM

- Emergency response team

- FIFO

- 5 S of area of work place