Call Us

-

-

Send Email

info@magnusindia.net

-

GST

27AAJPL0227B1Z8

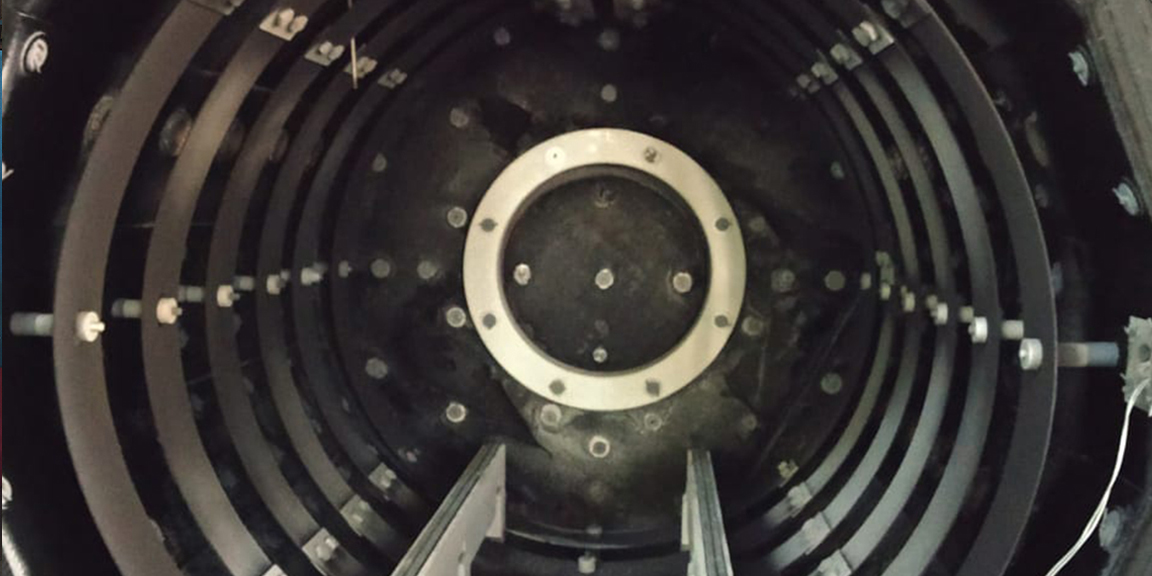

Shaker Hearth Furnace (Manufacturers)

Shaker Hearth Furnace Manufacturers in Pune, Chennai, Bangalore/Bengaluru

Our Products

Our Services

Magnus Industries is the leading Shaker Hearth Furnace Manufacturers in Pune, Chennai, Bangalore/Bengaluru. Our Furnace is an industrial furnace that is primarily used for hardening, carburizing, and annealing of steel and other metals. It has a unique design that allows for the shaking of the workload inside the furnace to ensure uniform heating and cooling.

Our furnace helps in the production of metal products used in various applications such as mining, oil and gas, and heavy engineering.

Properties

- Robust Construction – The furnace is built using high-quality materials such as cast iron, steel, and refractory materials to withstand high temperatures and harsh working conditions.

- Shaking Mechanism – The furnace has a shaking mechanism that allows the workload to move back and forth during heating, which provides uniform heating and cooling of the metal parts.

- Digital Controls – It is equipped with digital controls that enable precise temperature regulation, allowing for consistent heat treatment of the metal parts.

- Versatile – The Shaker Hearth Furnace can be used for different applications such as hardening, annealing, case hardening, and normalizing of metals.

Applications

- Heat Treatment – Shaker Hearth Furnace is used in the heat treatment of metal parts to improve their mechanical properties such as hardness, ductility, and strength.

- Aerospace Industry – The furnace is used in the aerospace industry to treat materials such as titanium alloys, which are used in manufacturing airplane parts.

- Automotive Industry – – It is used by automotive manufacturers to harden and nitride crankshafts, camshafts, and other engine components.

- Tool and Die making - The furnace aids in the manufacturing of precision tools and dies by hardening, carburizing, and nitriding them.

Shaker hearth furnaces are important for a variety of applications, including:

- Heat treatment: Shaker Hearth Furnace are used to heat treat a variety of materials, including steel, aluminum, and titanium. Heat treatment is a process that changes the properties of a material by heating it to a specific temperature and then cooling it in a controlled manner. This can improve the strength, toughness, and other properties of the material.

- Carburizing:These furnaces are also used for carburizing, which is a process that adds carbon to the surface of a material. This can improve the hardness and wear resistance of the material.

- Nitriding: It can also be used for nitriding, which is a process that adds nitrogen to the surface of a material. This can improve the hardness, corrosion resistance, and fatigue resistance of the material.

- Other applications: Offered furnaces can also be used for a variety of other applications, such as annealing, stress relieving, and brazing.

Advantages:

- Uniform heating: The shaking action of the hearth ensures that the materials are heated evenly throughout the furnace. This is important for heat treatment processes, as it ensures that the materials achieve the desired properties.

- High throughput: These furnaces can process large quantities of materials quickly and efficiently. This is important for applications where large volumes of materials need to be heat treated.

- Flexibility: It can be used for a variety of heat treatment processes. This makes them a versatile option for a variety of applications.

Offered furnaces are an important tool for a variety of applications. They offer a number of advantages over other types of furnaces, making them a versatile and efficient option for heat treatment.

Here are some additional benefits of Shaker Hearth Furnace:

- Reduced labor costs: It can be operated unattended, which can lead to reduced labor costs.

- Improved safety:These furnaces are designed to minimize the risk of fires and explosions.

- Reduced environmental impact: It can be operated in a controlled atmosphere, which can help to reduce emissions.